I know... it's Thursday. Late Thursday. This should have been posted yesterday, but let's pretend it's still Wednesday.

Welcome back to Wayback Wednesday, the day we look back in time at the works of Christine Frederick and other pioneers in home economics.

Welcome back to Wayback Wednesday, the day we look back in time at the works of Christine Frederick and other pioneers in home economics.

In New Housekeeping: Efficiency Studies in Home Management, Frederick performs an in-depth review of the ergonomics of washing dishes. From the height of the sink, to the placement of the tools, to the specific motions of each hand. The idea being that for work to be performed optimally, it needs to be done with ease. Physical straining cause by poor ergonomics makes work harder.

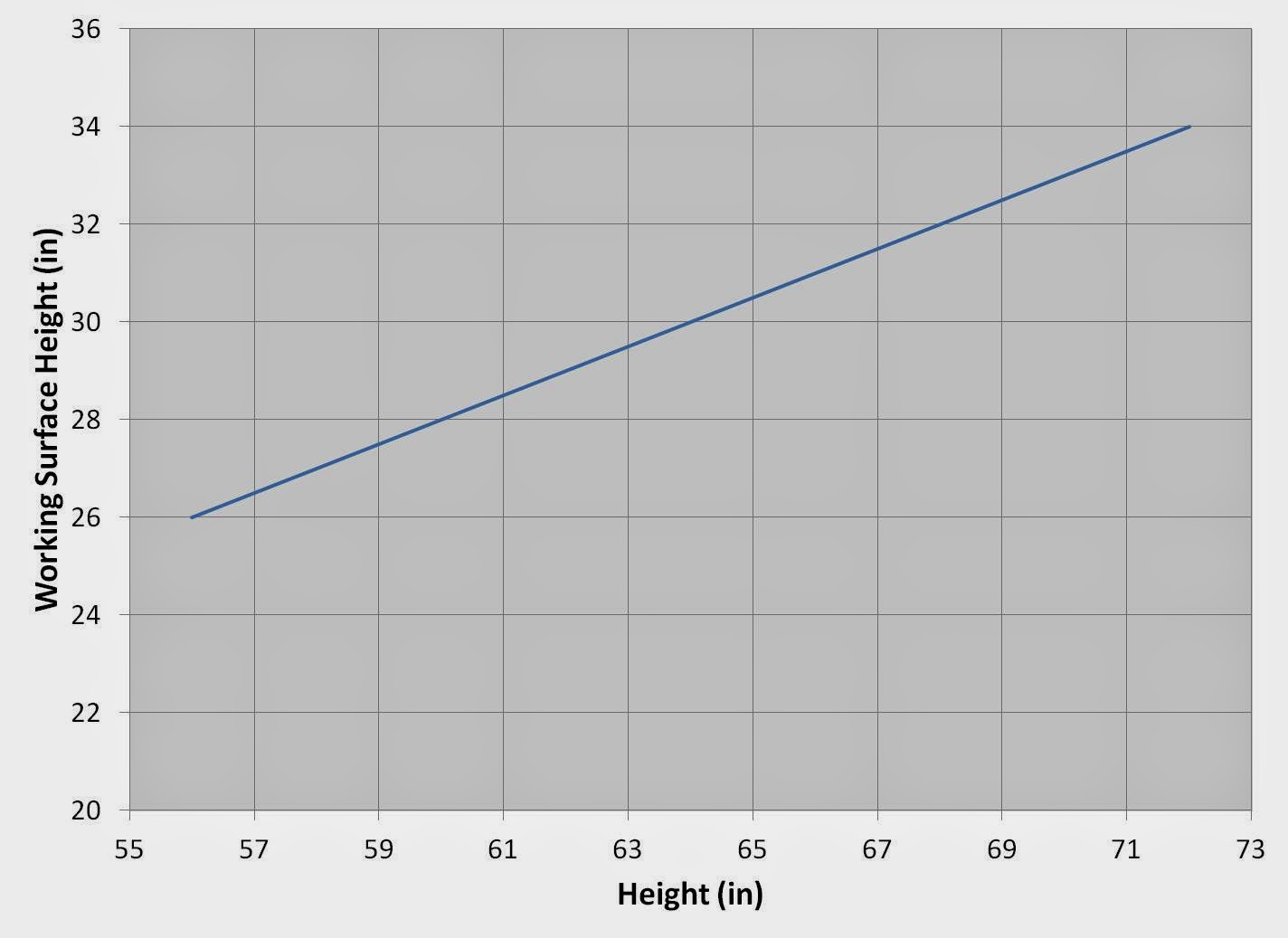

Included in her study was a table showing what the proper work surface height should be for people of various heights.

Frederick noticed that many of the working surfaces in her home were not optimized for her height. This meant that every task she performed was taking more effort than it needed to. She also tried to ensure that tasks didn't require any unnecessary bending or lifting. All of these are modern elements of ergonomics for work centre design.

Ironing is one task that Frederick's suggests would benefit from a proper work surface. Not only height, but also sturdiness. She writes;

I decided to put her principle of a proper work surface height into practice when I did the ironing this week. This was a qualitative study, I really should have measured the time it took to iron a shirt with each working surface height. I might recreate it during another wash day.

To calculate the correct working surface height, Frederick provided a table and a formula. I've converted it to a graph here for ease of use.

"In ironing, I found that my boards just like the sink, was not at the right height. It was so high that I couldn't obtain enough purchase on my iron without extra effort. I simply lowered the board, made it very steady, and thus helped my efficiency." (Frederick 1912)

I decided to put her principle of a proper work surface height into practice when I did the ironing this week. This was a qualitative study, I really should have measured the time it took to iron a shirt with each working surface height. I might recreate it during another wash day.

Now, I am not a tall person. Okay, that's probably an understatement, I'm short. My suggested working surface height is 28 inches. I have been setting up the ironing board at 32 inches.

The difference can really be seen in the angle of my elbows. At the lowered working height, my arms are almost straight down at a more natural angle. At the original height, I had to hold my arms in a bent position.

Sure enough, the lower board felt much more comfortable. It took less effort, less strength and I was able to finish quicker.

So how does this compare to present day ergonomic standards?

Ironing these days is very different than ironing in the early 1900s. Electric irons were just being released. You were lucky if you had one that was self-heated using coal or gas, these novelties were considered great time savers. Frederick wrote that an electric iron in 1912 would have cost $6, that is a cost today of almost $150. Would you spend $150 on an iron??

Needless to say, using a coal heated iron, or a metal one that needed to be heated on a stove is a lot heavier than a plastic one from today.

The Canadian Centre for Occupational Health and Safety has a good graphic that shows the different standing work surface heights for different types of jobs.

|

| http://www.ccohs.ca/oshanswers/ergonomics/standing/standing_basic.html |

In this case, heavy work isn't just lifting. It's defined as work that requires applying a downward force. It doesn't matter which iron you're using, you need to press down on the iron.

The CCOHS guideline says heavy work should be performed on a surface 7 3/4 - 15 3/4 inches below elbow height, which for average people works out to 25 1/2 - 37 1/2 inches. My elbow height is about 36 inches off the ground, so a work height of 28 inches falls nicely in this range (for a short person).

So for the last 18 years, I've been setting up my ironing board 4 inches too high. I'm guessing this is because my father, who is well over six feet tall, taught me to iron.

I wonder if he knows he was setting up the board two inches too low?